How does it work?

Most mechanical freezers operate around -40⁰c leading to a much slower freeze. Liquid nitrogen (LIN) freezes the moisture in the product far quicker than any mechanical freezing process. This leads to much smaller ice crystals, causing less damage to cell membranes. LIN can be utilised in freezer tunnels, batch freezers and through injection systems, where the liquid is mixed into the product itself while being mixed or formed.

‘Try our freezing calculator to create your own customised comparison of cryogenic to mechanical freezing times’

Add in Smart Technology

Freshline® Smart Technology is an integrated service to our cryogenic freezing process, allowing you to monitor, review and interact with data from your Freshline® cryogenic freezing tunnel and liquid nitrogen tank

The technology uses the latest sensors and wireless communication technology to advise process optimisation based on advanced analytics and track key process parameters, ultimately improving product quality whilst minimizing waste and costs.

Cryogenic vs Mechanical Food Freezing

Ask the Expert

Jahnavi Sheth

Food Cryogenics Technical Expert, UK

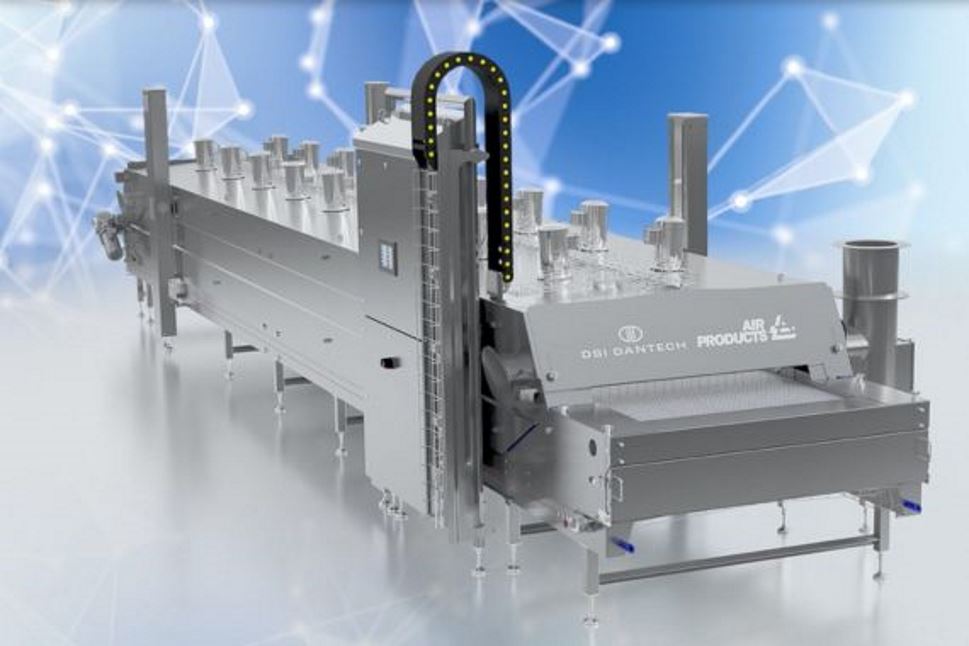

DSI Dantech Collaboration

Air Products and DSI Dantech have combined their Food Freezing knowledge and equipment manufacturing experience to bring the most advanced cryogenic freezing technology to the market. Together we proudly generate a cleaner future with a sustainable and reliable supply chain in Europe.

News & Views

Air Products In The Press

Are you wondering if cryogenic freezing is right for you?

Book a free consultation with one of our experts.

Freshline® Solutions for Plant-based Foods

Our Freshline® solutions preserve plant-based products, maintaining same taste and texture as fresh, while ensuring best shelf-life. Together -with our customers- we innovate to minimize food waste and optimise costs, delivering high-quality plant-based products.

Freshline® Smart Technology

Enter the world of smart cryogenic freezing. Control and optimize your gas consumption and food manufacturing processes, anytime and anywhere.