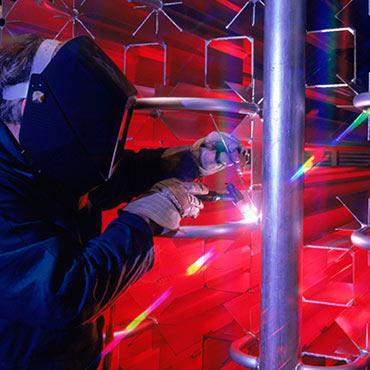

Process gases designed for welding carbon, carbon manganese and low alloy steels

WE HAVE GAS SOLUTIONS FOR YOUR BUSINESS – SELECT BELOW

Process gases designed for welding stainless steels

Process gases for high-quality welding of aluminium and its alloys

MIG/MAG welding gases designed to deliver optimum performance

TIG welding gases designed to improve weld quality and to reduce rejects

Air Products gas experts will help you determine the most economical supply option for your particular application and geographic location. Industrial gases are typically provided in gaseous and liquid form through a variety of supply systems.

Investing in robotic welding equipment is a significant financial commitment. Ensure you maximise your welding output capacity

Going the extra mile to ensure significant gas savings and improved weld quality

Welding Equipment

Maxx gases are proven to lower your welding cost per metre welded

There are 9 key areas of your operation where Maxx gas can have a positive impact. Contact us to see where we can generate savings for you.

|

Reduced gas consumption |

Reduced power usage |

Improved weld quality |

|

|

Faster welding speeds |

Reduced wire usage |

Less post-weld work |

|

|

Equipment saving |

Faster change-over times |

Improved safety |

Understand the hazards associated with weld fume and range of available control measures.

Download our e-book for detailed information and advice.

We offer a full range of both online and onsite safety training.

Online safety training starts at just £60 and provides certification for 3 years – ideal of anyone handling compressed gas cylinders.

We can offer advice and support with welding procedures and specifications in addition to the range of services our team of qualified welding experts offer.

See for yourself

Book a free welding gas demonstration with our team

News and Views