5 reasons to crust freeze your products prior to slicing them

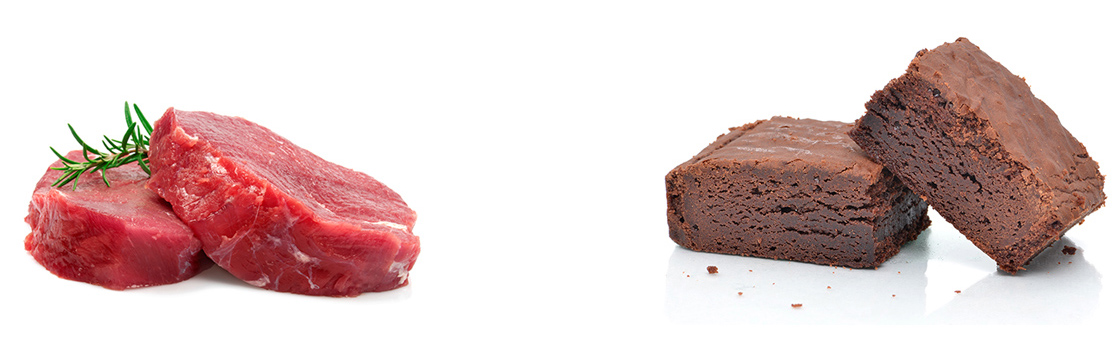

- Yield optimisation / waste reduction: By quickly freezing the very outer layer of a food product, the resulting thin crust protects the food from tears or damage during the slicing step. This means minimal losses and a higher quality final product.

- Increased processing speed: The crust frozen product withstands higher cutting speeds allowing you to speed up the cutting step with limited product damage.

- Bottleneck alleviation: For those of you cutting or slicing warm product, you don't need to wait until your product has cooled down in a cold storage.

- Thin slices: the hardened product surface can help you produce thinner slices.

- Food safety & quality: Because only the surface of the food is quick frozen, the product retains its quality and remains classified as 'fresh'.

Why cryogenic rather than mechanical freezing?

View Video →

Book your free consultation with one of our food experts today

tell me more →

What is crust freezing?

Crust freezing or hardening of a food product consists in freezing a very thin layer of its outer surface. This process can be done either in a batch or continuous process. Generally, for space, speed and quality reasons, food processors use a compact cryogenic freezer which achieves the task within only a few minutes. After that, food processors profit from the temporarily hardened surface to pass the product through their cutting or slicing equipment.

Our experts will be happy to assist you with any additional question you may have and help you test this process on your products.